Automation and Its Impact on Productivity and Workers

Lessons from the History of the Car Industry

1 Introduction

Over the past decade, we have witnessed the emergence of a wide range of new technologies with significant transformative potential. A major wave of automation is anticipated – particularly in industry – expected to profoundly affect productivity and the nature of work. However, the true extent of this impact remains to be seen. This article explores how we arrived at this point by drawing on past experiences and adopting a long-term perspective. It is not the first time such debates have emerged. Indeed, throughout history, industrial production has undergone several waves of automation. This raises a central question: What was the impact of the recurrence of such waves? Were existing structures, systems and practices radically replaced or was it a process of incremental change?

The following analysis seeks to answer this question by reflecting historical developments and drawing lessons from previous waves of automation. The key guiding questions are:

1) How has automation evolved over time? Has it progressed gradually or in disruptive leaps? What is the current level of automation in production, and how far are we from achieving full automation?

2) What has been the actual impact on productivity and workers?

Rather than relying on promises or fears surrounding new technologies, the focus lies on empirical analysis – examining concrete developments in production areas, typically embedded in complex process chains and shaped by product- and process-specific requirements and challenges. On this basis, the study aims to assess real changes and trace their long-term trajectories.

The study focuses on the automotive industry, a key sector of the 20th century. With over a century-long history, it remains one of the most significant fields for the application of automation technologies. The analysis centers on three major car manufacturers: Ford, Toyota, and Volkswagen (VW). These mass producers, comparable in size, have each played pioneering roles in automation at different points in time. The article examines selected production segments within plants located in each company’s country of origin.

Emphasis is placed on production processes. Although the evolution of product design and distribution is not the primary concern, changes in vehicle architecture are reflected in the analysis where relevant. Early automobiles differed greatly from today’s vehicles, yet many basic structural and operational principles have remained consistent, allowing for meaningful comparisons over time.

Given the broad timeframe and scope, the analysis is necessarily selective. It addresses only a specific segment of the industry – focusing on end producers rather than suppliers, and excluding such economic factors as profitability, corporate structures, and policy dimensions related to automation.

The study is structured as follows: Section 2 introduces the data and core concepts used in the analysis. Section 3 traces the trajectories of automation in the studied companies, based on the core assumption that historical context is essential for understanding the dynamics that drive or hinder automation processes, as well as the differences in company-specific approaches. The section is structured into three sub-sections. The first examines developments at Ford from 1910 to 1970, focusing on the role of automation within the production system that evolved at the company early in this period. The second analyzes the period from the 1950s to 1990, comparing the distinct automation strategies pursued by Toyota and VW, and concludes with an assessment of the level of automation achieved by 1990. The third explores VW’s trajectory from the 1990s to the mid-2010s, emphasizing efforts to align Lean Production principles with an automation-centered strategy. Section 4 analyzes automation’s impact on productivity and the occupational structure of the production workforce. In two sub-sections, it identifies developmental patterns across companies and contextualizes them within existing academic discourse. Section 5 addresses whether the emergence of electric vehicles (EVs) signals a new phase of automation, with the potential to once again reshape production processes and employment structures. The study concludes by drawing on historical developments to inform contemporary debates on automation and industrial change.

2 Data and Core Concepts

This article draws from a more comprehensive study on the subject (Jürgens, 2023), and bases its findings on academic literature, company records, and archival materials from Ford and VW. For the period beginning in the 1980s, it also integrates findings from the author’s empirical studies at all three companies, including interviews with managers, workers, and employee representatives, as well as on-site observations (Jürgens et al., 1993; Jürgens & Krzywdzinski, 2016).

Regarding the definition and empirical measurement of automation, different approaches can be observed. Reflecting different points of interest, automation is defined as the replacement of some or all functions performed by humans by machines, or, vice versa, the decrease of machine dependence on humans. The German Institute for Standardization (DIN) defines automation in the latter sense as “the setting up of a system so that it operates as intended, wholly or in part, without human intervention” (DIN 19233). The concept of automation is technology-independent. Within research, it is occasionally replaced by such terms as mechanization, computerization, and robotization, which refer to specific technologies applied.

The usual measure is the degree of automation. This is the ratio of the number of automated process steps to the total number of process steps required for production in a well-defined area (see also DIN IEC 60050-351). In most cases, the degree of automation is measured for the main activities in a specified area, such as welding in a body shop. However, this approach considers only the (direct) production activities. Measurement of the degree of automation including supporting (so-called indirect) activities, such as quality assurance, maintenance, or material supply, would require additional measurements specific to each function. In all cases, the measurement of the degree of automation demands in-depth insights into the production processes and is hardly possible without insider knowledge.

Another way of measuring the degree of automation is to examine the extent to which machines can operate independently of human intervention in performing the functions for which they were designed. Bright (1958, 17) proposed the term “automaticity” for this purpose. Based on his scale of mechanization, he classified contemporary automation technologies into specific levels according to the criterion of automaticity. In the 1950s and 1960s, various authors proposed similar stepwise models (Ulrich, 1968); however, subsequent research did not pursue this approach further. Current approaches that use the number of robots or digitized equipment as indicators of automation are rarely sufficiently differentiated to be of much analytical value (see Krzywdzinski, 2021).

Although the topic of automation has long sparked heated debates and generated an enormous volume of literature, there is a lack of detailed data on the actual state of automation within specific industries and companies. One such study was conducted in the second half of the 1950s by the head of the machining department at the Daimler-Benz plant in Untertürkheim (Moll, 1961; Moll & Ulbricht, 1957). The study mapped the processes in a production area where, at the time, roughly 12,000 employees worked on approximately 5,000 machine tools.

Datasets that cover longer historical periods are even rarer. The major reason for this is that analyzing automation effects over a longer period creates problems related to the influence of factors that affect the volumes of work and the kind of operations required in specific production units at a given time. Among the most important influencing factors are: (a) efficiency improvements through changes in work organization; (b) changes in product design to make the product easier to manufacture, and measures to reduce the number of product variants and thus the complexity of production; and (c) organizational measures, such as the outsourcing of work areas.

The situation is similar when measuring productivity. In the following, productivity is consistently used to refer to labor productivity measured in physical units of parts or complete products. Although it is a key indicator for the companies, it is usually kept secret for competitive reasons. In addition, the comparison of productivity levels creates similar problems of keeping influencing factors under control, as in the case of automation.

3 Automation in the Automotive Industry over Time

3.1 Ford’s Mass Production System and Detroit Automation (1910-1970)

When Henry Ford planned his factory for the mass production of the Model T, he was able to draw not only on production techniques developed in the 19th century, but also on the foundational principles of a production system that had emerged even earlier. By the mid-20th century, this became known as the American System of Manufacturing (ASM) (Hounshell, 1984; Rosenberg, 1963).

The ASM was based on a specific combination of product and production principles: the use of interchangeable parts, single-purpose machines, flow-oriented production processes, and unskilled labor in direct production. The origins of this development, which reach back to the 18th century, cannot be described in detail here due to space constraints. By around 1850, the most advanced U.S. factories had succeeded in achieving full interchangeability of parts. From there, the ASM spread to other industries that embraced industrial mass production, such as watchmaking, sewing machines, agricultural equipment, and bicycles. Hounshell (1984) traced a direct line from these early adopters to the emergence of the automobile industry, while Abernathy and Corcoran (1983) described the auto industry as “the historical culmination of the American manufacturing system itself” (162).

Industrial-scale automobile production began in the early 1910s at Ford Motor Company’s Highland Park plant in Detroit. At the core of this system was the single-model policy centered on the Model T. The production setup was structured around the principle of flow production (Biggs, 1987). Machining processes were already highly automated at this stage. In 1914, the Highland Park plant operated more machines (approximately 15,000) than it employed workers (around 13,000) (Meyer, 1981). This high machine-to-worker ratio is a strong indicator of the use of single-purpose machines – each operation requires a dedicated machine operated by one worker. Most of these machines were used for manufacturing powertrains and chassis components. A striking example was the cylinder block production line. As Arnold and Faurote (1915) noted in their seminal study on Highland Park: “There is no hand work on this cylinder, there are but few operations made on one cylinder only at a time, and these single-cylinder operations are rapid” (73). Further to machining, many internal logistics processes were already automated, employing conveyor belts and cranes to move parts and materials.

The assembly line was introduced only after the plant had been in operation for several years. The automation of machining processes and the implementation of a flow-oriented layout had significantly accelerated parts production, placing increasing pressure on the comparatively slower, stationary assembly sections. Nearly a year of experimentation preceded the transition to line-based assembly. In fact, earlier trials had already been conducted at the predecessor plant to Highland Park (see Nye, 2013, 13). A major challenge was organizing the workforce for line production and synchronizing the assembly process with component manufacturing and supplier deliveries – classic industrial engineering tasks. Yet the most difficult part was preparing the workforce for the new pace of work, primarily the responsibility of lower-level supervisors and, behind the scenes, the personnel department. At the heart of this process was the question of how fast the lines could be run, and how narrowly worker tasks could be sub-divided. Ultimately, the one-minute cycle emerged as the optimum – the Fordist speed, which remains a benchmark to this day.

However, it quickly became clear that with a production volume approaching one million cars – as was soon the case at Highland Park – a one-minute cycle time would be far too long if only a single assembly line were used. This is easy to calculate based on the number of cars to be produced, the time required to build a single car, and the total working minutes available per worker per day, month, or year. Accordingly, Highland Park soon adopted a structure of multiple parallel assembly lines, which allowed Ford to respond flexibly to market fluctuations by shutting down or activating individual lines as needed. This parallel structure is often overlooked in the discussion of the rigidities of the Fordist system.

The insights gained during the early years of automobile production flowed into the construction of the River Rouge plant, which became the flagship factory of the interwar period. van Deventer (1922), editor of the journal Industrial Management, described the facility as a “perfectly timed, smoothly operating industrial machine of almost unbelievable efficiency” (131). The image of a machine for making machines, now a common metaphor for modern production systems, found one of its earliest and most iconic realizations here.

Everything about the plant was of enormous scale: With an annual capacity of over one million vehicles, it encompassed nearly the entire automotive production process, including such upstream stages as steel manufacturing, foundry operations, and even its own power plant. The number of single-purpose machines used at River Rouge far exceeded that of the Highland Park plant – many were colossal in size. At its peak, over 100,000 workers were employed at the site.

Each task was performed by a separate machine, requiring manual handling of workpieces between stages. This inefficiency in material handling prompted the next step in the development of single-purpose technology: the integration of multiple individual machines – and the transport between them – into fully linked systems known as transfer machines. Due to the tight coupling of the various elements, the single-purpose character of the equipment was reinforced, but it enabled a faster flow of production. This approach later became known as “Detroit Automation” and gained prominence after World War II (Hounshell, 2000).

A closer look at the various production areas shows that River Rouge far surpassed Highland Park in terms of both the number and technical sophistication of machines, particularly in machining operations. There is no data on the automation level in River Rouge, but we can assume that it operated at a similar level as German plants designed on its example. A study at Daimler-Benz in the mid-1950s (Moll, 1961) estimated that the degree of automation in machining operations had already reached 60 – 80% during and even before World War II. The foundry in the River Rouge plant, as reported by van Deventer in 1922, was already significantly automated. The press and body shops also featured a high degree of automation, using special single-purpose machines (e.g., multi-welders). Assembly work, by contrast, remained largely manual, although hand-held tools like spot welders and power screwdrivers were increasingly used. Manual transport and handling tasks were further reduced through the systematic deployment of conveyor systems. (For more detailed descriptions of machinery at River Rouge see Barclay, 1936).

Despite its technological advances, River Rouge was only able to realize its full potential during brief periods. Ford’s dominance during the 1920s gradually declined with the emergence of General Motors and Chrysler as significant competitors. GM eventually took the lead – mainly due to its strategy of product differentiation, including multiple models, frequent model changes, and annual facelifts, as well as a decentralized production structure (Tedlow, 1988). The highly centralized and scale-driven structure of River Rouge would prove too inflexible for this approach. Economic crises, lack of responsiveness to changing market demands, and the sheer number of employees – all of which turned the plant into a flashpoint for labor conflicts – transformed Ford’s industrial showpiece into a burden.

After World War II, two distinct strands drove the debate forward. The first was technological: New developments in electronics and early computer-based controls began to emerge – automated machine tools, industrial robots, automated guided vehicles (AGVs), and some early IT systems were being explored in research labs (Noble, 1986). However, these technologies were still in their infancy, and much of the surrounding discussion remained in the realm of science fiction.

The second strand concerned industrial relations and had more immediate practical implications. Against the backdrop of postwar reconstruction and expansion, unions recognized an opportunity to negotiate broader labor protections considering planned investments in new plants and automation technologies. In 1950, the United Auto Workers (UAW) signed a groundbreaking five-year contract with General Motors – soon followed by similar agreements with Ford and other manufacturers (Minchin, 2024). This “Treaty of Detroit” secured, for the first time, substantial social benefits for workers, including pensions and healthcare. In exchange, the union agreed to refrain from strikes for five years, giving companies the planning security needed to invest in plant modernization. The agreement laid the foundation for cooperative labor-management relations over the following decades and marked the beginning of postwar Fordism, wherein unions became active supporters of productivity-enhancing measures – wage increases were explicitly tied to productivity growth.

In 1946, Ford declared automation a strategic priority. The establishment of a special automation division signaled the company’s strong commitment to the topic. Even the term “automation” was coined by Ford at that time (see Jürgens, 2023). The flagship project was a new engine plant in Cleveland, Ohio, which began producing six-cylinder engines in 1951. The showcase of automation in the plant was, once again, cylinder block production. The system under consideration represented the first generation of equipment at the Cleveland plant and consisted of dozens of in-line transfer machines. The production line stretched nearly 400 meters and executed hundreds of different operations. Its operation required only one supervisor and two maintenance workers responsible for replacing worn tools and performing repairs (Nevins & Hill, 1963; Weber, 2003).

The system’s core consisted of transfer machines with integrated transport of workpieces between processing stations. However, this still represented conventional mechanization technology (Bright, 1958). In response to growing demands for flexibility, Ford pursued a different approach to dealing with this issue. A central element of its postwar modernization program was the decentralization of component production, which had previously been integrated within the River Rouge plant. Parallel structures of smaller plants were established for engine and transmission manufacturing, body stamping, and final assembly. This allowed the company to manage product variety more effectively by assigning specific vehicle models to dedicated facilities. In so doing, Ford adopted an organizational solution to the complexity challenges posed by increasing product diversification (see Abernathy, 1978).

Ultimately, contrary to the expectations of such scholars as Piore and Sabel in The second industrial divide (1984), a decisive shift toward flexible production systems did not materialize. As MacDuffie and Pil (1997) observed in a comparative study conducted under the International Motor Vehicle Program (IMVP) in the 1990s, “U.S. plants made much greater use of fixed automation than plants in other regions” (245).

In summary, the narrow scope of functional specialization – both of machinery and of workers’ task-related capabilities – established under the ASM enabled substantial productivity gains, but ultimately became a constraint when markets began to demand greater flexibility. The postwar availability of more adaptable technologies was not sufficient to overcome the entrenched complementarities that had developed within the system. It was only under exceptional circumstances that a viable alternative emerged: Toyota’s unconventional approach, which emphasized organizational innovation grounded in the potential of social cooperation, offered a path beyond the rigidities of the existing model.

3.2 Toyota and VW – 1950 to 1990: Contrasting Approaches towards Automation

3.2.1 Toyota (Japan)

Toyota represents a clear counterpoint to Western companies’ strong focus on technology and production-process automation. Founded in 1937, the company initially produced various types of trucks in small batches during World War II – a pattern that continued into the immediate postwar years. Toyota did not begin focusing on passenger car production until the early 1950s, and even then, overall production volumes remained low. Before output increased sharply in the mid-1960s, Toyota experienced nearly two decades of low and highly volatile production – conditions under which the Toyota Production System (TPS) gradually emerged.

During this period, the question of automation arose in a fundamentally different manner than in Western companies, which were already benefiting from the postwar economic boom. Much of the machinery used to manufacture complex components had been imported from the United States before the war and reflected pre-Detroit automation technology – single-purpose machines operated manually by dedicated workers. Accordingly, Toyota’s early automation efforts focused on modifying existing equipment to free up human labor for other tasks (Shingo, 1989). These modifications were often simple and implemented directly on the shop floor, such as by installing automatic shut-off switches that would stop machines when a disturbance occurred or when a production run was completed. The overarching objective was not to reduce labor, but to enhance its flexibility.

This philosophy also extended to other areas. Rather than turning to technology to solve production problems, Toyota typically looked first to improvements in work organization. A prime example is the Kanban system of the 1950s. Designed to control production flow in small batch sizes, Kanban is based on well-defined, rigorously applied organizational routines. “With Kanban, you don’t need computers,” remarked Taiichi Ohno – then head of the machining shop and later Vice President of Production at Toyota (Shimokawa & Fujimoto, 2009, 16; see also Monden, 1993). The emphasis on flexibility and organizational innovation gained special importance for Toyota. It enabled the company to produce multiple vehicle models on the same assembly line – a capability that would become a distinctive strength and competitive advantage in the decades that followed.

Toyota also pursued a fundamentally different approach to skill formation. The company did not seek to employ unskilled workers who could be hired “off the street,” but neither did it aim to recruit highly trained skilled workers in the German tradition. Instead, over time, Toyota developed a unique personnel system (Nomura & Jürgens, 1995; Jürgens & Krzywdzinski, 2016). All regular employees are granted de facto lifelong employment security and are expected to advance to more qualified, higher-ranking positions within their functional areas. To support this progression, the company offers ongoing training throughout an employee’s career. As such, automation measures that eliminate specific jobs do not threaten employment security or employees’ status (Nomura & Jürgens, 1995).

Toyota’s first mass production plant – Takaoka – was established in the mid-1960s. At this stage, the company began making significant investments in automation technology. As flexible automation was not yet available, Toyota initially adopted Detroit-style single-purpose machines, such as multi-welders. However, the company soon implemented measures to enhance production flexibility. In the press shop, quick die change procedures were introduced, while rigid welding lines were replaced by industrial robots within little more than a year in the body shop (Toyota, 2012). In the early 1980s, Toyota developed and implemented Flexible Body Lines (FBL), a system that enabled the welding of multiple car models on a single line (Krzywdzinski, 2021). Despite these advancements, vehicle assembly remained largely manual.

By the late 1980s, Toyota, like many other Japanese manufacturers, faced serious labor challenges. A growing labor shortage and increasing public criticism of working conditions in the manufacturing sector led to growing concerns about recruitment. In response, Toyota began considering – albeit cautiously – the automation of assembly work. Rather than fully committing to assembly automation, the company adopted a dual-track strategy. One plant, Tahara, underwent a comprehensive automation program, while another, the Kyushu plant, was built with a focus on improving working conditions through redesigned work processes and new forms of work organization. The results quickly became evident: Toyota deemed the automation initiative at Tahara a failure and subsequently dismantled it, while the Kyushu plant was regarded as a success (Shimizu, 1998).

Toyota has since taken its philosophy even further. In 2018, the company unveiled a newly designed assembly hall at the Takaoka plant, presented as a model factory of the future. The concept aimed to minimize automation while maximizing flexibility through organizational solutions. Multiple vehicle models can be assembled on a single line – but this flexibility is enabled by process design rather than advanced robotics. Only a single robot remains in the hall (Schmitt, 2019).

Overall, Toyota has remained far more critical and selective in its approach to automation than most other automotive manufacturers. The principles of continuous flow and operational flexibility, especially in response to volatile market conditions, have consistently taken precedence over automation for its own sake.

3.2.2 Volkswagen (Germany)

VW was founded under the Nazi regime as part of an effort to establish mass automobile production in Germany. Ford served as the primary role model – both in its single-model product policy and its production system. The Wolfsburg plant was modeled closely on Ford’s River Rouge complex in terms of scale, layout, equipment, and even workforce structure (Rieger, 2013; Mommsen & Grieger, 1996), and production was ready to begin by 1938. However, VW was only formally established as an independent automotive company in the late 1940s.

A sharp increase in demand during the mid-1950s, driven primarily by rising exports, brought automation to the forefront. Labor shortages – regardless of skill level – compounded the pressure for productivity gains. Unlike the other two companies studied, labor unions became a central and enduring force at VW, influencing corporate decision-making from early on. Automation efforts at Wolfsburg concentrated primarily on the press and body shops. The equipment followed the Detroit model, relying on single-purpose machines. Since German engineering firms at the time lacked the necessary expertise in this area, the machines were developed in-house by VW’s own engineering team. Their innovative solutions for automating body shop operations attracted attention and recognition from international industry experts (Abernathy, 1978). The success of VW’s internally developed automation solutions led to a strategic decision in the early 1970s to pursue the in-house development and production of industrial robots. In the longer term, the company even considered establishing itself as a supplier of automation technologies.

A key factor in this consideration was VW’s vocational training system which became a pillar of company performance and a point of corporate pride. 1 Normally, after completing vocational training, workers were first employed in production, where they often worked in jobs with low skill requirements. Automation measures promised to create jobs with high skill requirements and thus open up career paths for workers with vocational degrees. At the same time, the high employment security in the company and the codetermination rights of the works council ensured that workers were not afraid of redundancies due to automation (Kern & Schumann, 1984; Kuhlmann, 2004).

In the early 1980s, automation efforts focused on assembly – specifically on the Golf/Jetta series, which was slated for production volumes exceeding half a million units. A key objective, explicitly agreed upon with the labor union, was to raise the level of automation in assembly to 25%. This plan was meticulously negotiated with the works council and IG Metall. The resulting process layout was highly complex and encompassed five production lines and differently structured production areas (for a more detailed description, see Jürgens, 2023):

- A pre-assembly area, where components were assembled into larger modules.

- A fully automated zone, known as the Technical Center, where most cars passed through long rows of transfer machines. These provided a limited degree of flexibility to handle model variants and optional equipment.

- A manual line for special vehicles, which relied primarily on conventional assembly work.

- The intention behind this complex layout was clearly to achieve efficiency through economies of scale – using transfer machines in areas with standardized tasks while relying on manual labor or robots in the remaining sections. Contrary to expectations that robots would become the dominant technology in Hall 54, they ultimately accounted for as little as 2.5% of the automation equipment.

Despite its ambitious scope, the Hall 54 project fell short of its productivity and cost reduction targets (Bartl, 1988). Contributing to this failure were frequent technical malfunctions in the automated systems, compounded by the layout’s complexity. More fundamentally, the concept’s core weakness lay in the limited flexibility of the automation, which proved unable to cope with the increasing complexity of new vehicle models. The planners clearly underestimated the rapid rise in model variety and equipment options. Consequently, major restructuring and adaptation became necessary only a few years after the system’s launch.

Regarding the trend toward increasing product differentiation, the planners envisioned a segmented production structure, employing different technologies and manufacturing systems tailored to specific product variants:

- a highly automated, high-speed line system for large series with limited variant diversity;

- flexible, robot-assisted systems for mid-sized series with a broader range of variants;

- and combined systems featuring manufacturing cells, manual assembly, and driverless transport systems for small series and “exotic” models (Wilhelm 1997, 155).

Even within this differentiated approach, achieving efficiency through economies of scale remained central.

As this section has shown, Toyota largely circumvented the stage of single-purpose automation, pursuing a more flexible, integrated development path from the outset. In contrast, Volkswagen remained tied to a legacy of Detroit-style, dedicated machinery. American automakers, as noted earlier, faced path dependencies that limited their capacity to adopt more flexible technologies.

Yet, despite these divergent technological strategies, the actual level of automation achieved across production areas by the early 1990s exhibited only minor variation, as indicated in Table 1. While firm-level data were available only for Volkswagen, the use of industry-wide figures for Ford and Toyota – reflecting U.S. and Japanese averages – suggests that these companies converged at a similarly high level of automation. This convergence points to the presence of strong structural constraints within automotive manufacturing that overrode differences in firm-level innovation strategies.

Table 1 underscores this pattern: automation had reached saturation in core areas such as machining, pressing, and body construction—areas characterized by high repeatability and standardization. Even in the paint shop, automation was well advanced. In contrast, final assembly remained a clear outlier: here, manual labor still dominated. While Volkswagen made efforts to depart from this norm, two-thirds of its assembly tasks were still performed manually.

Table 1: Levels of Automation at the Beginning of the 1990s

|

Machine shop |

Pressshop |

Bodyshop |

Paintshop |

Assembly shop |

|

|

Average of JapaneseCarmakers 1993 |

93% |

94% |

91% |

51% |

10% |

|

VW plant Wolfsburg 1991 |

n/a |

95% |

80% |

80% |

33% |

|

Average U.S. car plant in 1989 |

n/a |

n/a |

94% |

59% |

1.5% |

Sources: For Japan: Fujimoto (1997, 64-66), Average of the most highly automated production lines, with 9 Japanese automotive manufacturers surveyed. For VW: Special edition of Automobil Produktion (1991). For the U.S.: Holbein and Pil (2000, 53).

Despite similarities in automation levels, the underlying approaches to automation differed significantly. Toyota, for instance, largely bypassed the phase of single-purpose automation and adopted flexible production technologies at an early stage. In contrast, VW continued to rely on traditional Detroit-style automation, even after establishing itself as a successful robot manufacturer. American carmakers found it particularly difficult to move away from their legacy of single-purpose machinery.

3.2.3 VW: 1990 to mid-2010s

The 1990s brought an important change in the discussions about automation, with automotive companies turning to Lean Production and TPS concepts. The following focuses on the developments at VW, where questions of automation continued to play a key role.

A significant contextual development during the 1990s was the shifting geopolitical landscape, marked by the opening of new markets and the emergence of low-cost production sites (Pavlinek, 2025; Jürgens & Krzywdzinski, 2009). This transformation was closely tied to the restructuring of supplier relations and the outsourcing of operations, which created opportunities for cost reduction and efficiency gains without the need for further automation. The adoption of Lean Production and TPS principles, such as teamwork and Kaizen, further reinforced labor-saving effects while minimizing reliance on automation (Jürgens, 1998; Schumann et al., 1994).

At the same time, an opposing trend intensified: the growing diversity of car models, variants, and equipment options. Mirroring developments in the United States, new vehicle categories, such as minivans, sport utility vehicles (SUVs), and crossover models, gained increasing popularity (Fisher et al., 1995). This diversification significantly heightened the complexity of production processes, particularly in final assembly.

Moreover, increasing regulatory requirements on emissions, vehicle safety, and environmental standards, along with an emphasis on quality and refinement, further required high investments in new production equipment during this period (Pardi, 2021). However, such investments were primarily concentrated in areas that had already exhibited high levels of automation, such as machining, press, and paint shops. Consequently, the overall impact on the degree of automation across the production system was limited.

An illustrative example is the transformation of press shop operations beginning in the 1990s (Jürgens, 2023). Traditional transfer lines composed of sequential press machines were replaced by large-scale multi-stage presses (Großteil-Stufenpressen) capable of producing major body components. One such machine, commissioned in 2010, manufactures various parts (e.g., roof and side panels) over a single day. Its dimensions are immense: 80 meters in length, 20 meters in width, and 11 meters in height. Tool changes are largely automated and completed within minutes.

The direct automation effect in the press shop was minimal, as automation levels were already close to 100%. However, the introduction of these large presses had a significant impact on subsequent body shop operations. The ability to press entire large components reduced the need to weld together numerous smaller parts. While such a shift would have displaced many manual workers in earlier periods, these welding tasks had long been performed by robots by this time. Consequently, it was not human labor, but robotic capacity, that became redundant. As a result, the net effect on automation levels in the body shop was also limited.

A similar pattern emerged in the assembly area, where VW ultimately abandoned the Hall 54 concept in 1997. The “Technical Center” and the previously implemented flexible assembly line were dissolved. The company transitioned to parallel production lines, each equally equipped to produce all vehicle variants. In place of traditional transfer lines, these new lines were staffed with robots, leading to a significant increase in the number of robots deployed. However, this shift did not result in workforce reductions, and the overall degree of automation rose only marginally – to approximately 33%. Importantly, the objective was not automation per se, but rather the establishment of a smooth production flow and greater process transparency – goals aligned with Lean Production principles (Jürgens, 2023).

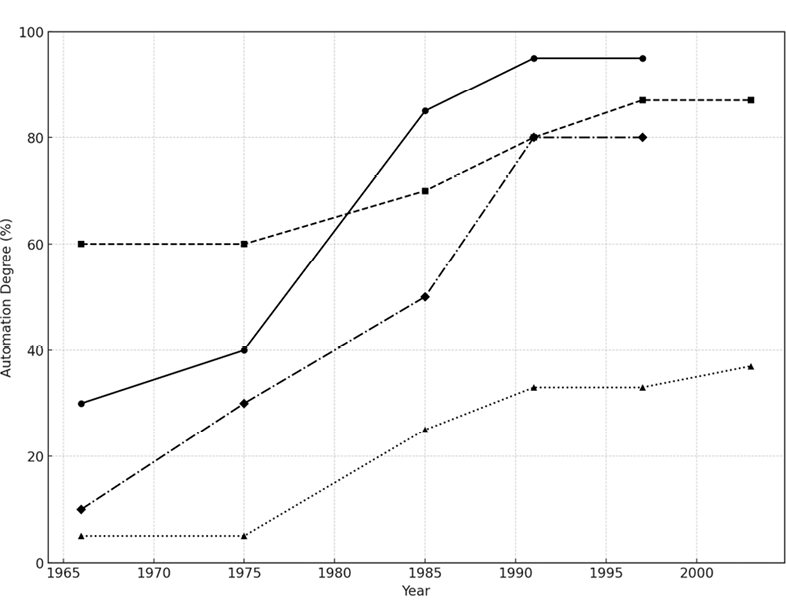

In retrospect, the period around 1990 was not only the peak, but also the turning point in the development of automation. Figure 1 illustrates the developments using the case of VW. By the 1960s, body shop automation had already reached a high level, and had climbed continuously since then to reach well above 90%. The press and paint shop automation began with low levels in the postwar period, but reached almost complete automation in the 1990s. Automation in the assembly started to increase only in the 1980s, reached around 30% in the 1990s, and has remained at this level since then, as though an invisible barrier emerged that could not be crossed.

Figure 1: Development of Automation Levels in Major Shops at the VW Wolfsburg Plant (1966–2012)

Note: Data are only partially available. Sources: Kern and Schumann (1984, 66), Granel (1985, 17); Automobil Produktion (1991, 1997, 2003), and Volkswagen Besucherdienste (2012). For more details, see Jürgens (2023, Chapter 9).

As the analysis throughout this chapter has demonstrated, successive leaps in technological development did not lead to the wholesale replacement of older systems, but rather to a layering of new technologies atop existing ones. The legacy of Fordist single-purpose machinery persisted far longer than is commonly assumed. The only significant disruption to this continuity occurred in the early 1990s with the adoption of Lean Production and the TPS. Consequently, the widely circulated narrative of technologically induced industrial revolutions (Schwab, 2016) – progressing from the steam engine to electrification and the assembly line, then to computers and robotics, and finally to autonomous systems and machine learning – is not supported by the empirical evidence presented here.

4 Consequences for Productivity and Employment

4.1 Productivity

In what way has the automation process affected productivity in the automotive industry? Ford’s Highland Park plant led to an increase in productivity unprecedented in the history of automotive manufacturing. Henry Ford (or his ghostwriter Samuel Crowther) wrote in his autobiography My Life and Work: “A million skilled workers working by hand could not even approximate our present daily output” (1922, 75).

The figure was not entirely arbitrary. In the first year of Model T production (1908), 1,776 labor hours per car (including both direct and indirect labor) were required at the predecessor plant to Highland Park. By the final full year of production (1926), this figure had fallen to just 53 hours – representing a 97% reduction, or a more than 33-fold improvement in productivity (Wilson, 2015).

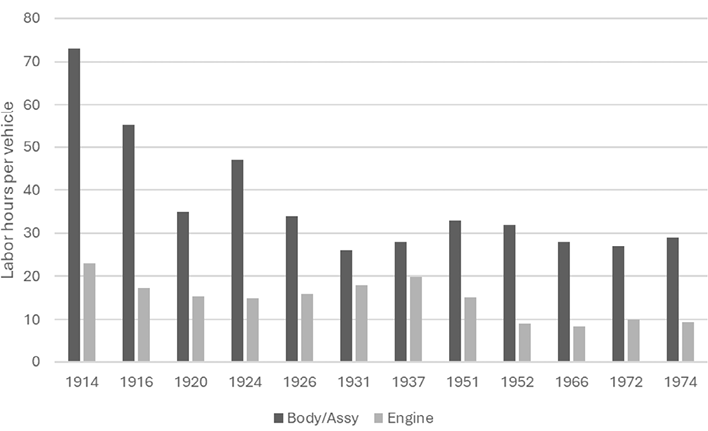

When comparing Ford’s achievements in the 1910s with those of later production sites, it is appropriate to confine the analysis to specific areas of production. The following discussion is based on a study conducted by Abernathy (1978), and examines developments at Ford in the United States between 1914 and 1974. The analysis focuses on engine production as well as body and final assembly operations. Figure 2 presents data for selected years, excluding the sharp declines associated with the model changeover following the discontinuation of the Model T in 1927/28 and the postwar resumption of automobile production after 1945.

Figure 2: Hours Worked per Vehicle in the Body and Assembly Shop and Engine Production at Ford’s North American Plants (1914 to 1974)

Note: The data encompass different vehicle models and production plants. Labor hours reflect the total workforce, including both direct and indirect employees. In some cases, data points were interpolated to align with a common time scale. Source: Abernathy (1978, 178–179).

Figure 2 illustrates the enormous increase in productivity throughout the Model T’s production in terms of body and assembly operations. In 1914, these processes required 73 labor hours per vehicle. By 1926, the final full year of Model T production, this number had declined to 33 hours, which corresponds to a productivity improvement of around 120% and an average annual increase of almost 7%. By 1974, labor hours for body and assembly operations per vehicle had declined further to 29 hours. Therefore, within almost 50 years, productivity only increased by approximately 14%, with an average annual productivity growth of 0.27% per year. A more recent benchmark is provided by the Harbour Report (Harbour & Higgins, 2008, 97), which indicates that by 2008, these operations required 24.3 labor hours. This reduction reflects a productivity improvement of roughly 19% over 34 years, corresponding to an average annual growth rate of about 0.5%.

Turning to engine manufacturing: In 1914, producing an engine required 23.1 labor hours per vehicle. By 1926, this had been reduced to 16 hours, representing a productivity improvement of approximately 44% over 12 years, equivalent to an average annual increase of about 3.1%. Between 1926 and 1974, the figure declined from 16 to 9.5 hours. During this period, productivity increased by approximately 69%, corresponding to an average annual increase of 1.1% – almost double the rate achieved in body and assembly operations. According to Harbour and Higgins (2008, 101), by 2008 the labor requirement had dropped further to 4.3 hours per engine in a Ford U.S. plant. This reflects an additional productivity gain of about 121% compared to 1974, with an average annual growth rate of approximately 2.4%.

While these numbers underscore how the higher degree of automation in engine production consistently delivered measurable gains in labor productivity, they also illustrate how the pace of improvement gradually declined over time.

It would be wrong, however, to attribute productivity growth primarily to automation and new technologies. Other factors – such as work intensification during certain periods – played an equally, if not more, important role (Sward, 1948). Another notable example is the introduction of the Five-Dollar Day minimum wage in 1914, which led to a dramatic reduction in employee turnover: from 370% in 1913 to just 16% in 1915 (Raff & Summers, 1987, 79). While much of the historical debate has focused on the implications regarding the price of the car, its effect on productivity was also substantial. Lower turnover reduced training burden for new employees, thereby improving labor efficiency and productivity.

Taken as a whole, Figure 2 suggests a significant slowdown in productivity growth since the initial boom during the early decades of mass automobile production. After the “Highland Park miracle,” why did the automotive industry lose its productivity momentum? By way of explanation, Abernathy (1978) argued that firms, by increasingly concentrating on incremental efficiency gains, gradually lost the ability to pursue more radical innovations. Gordon (2016) interpreted the slowdown as a result of a broader historical trend: the diminishing impact of the major innovations of the Second Industrial Revolution – particularly Ford’s introduction of the assembly line.

Based on the analysis, this article argues that the slowdown in productivity dynamics since the 1970s can largely be attributed to increased product differentiation and shorter model life cycles. A similar argument was proposed by Schonberger (2006), who linked Toyota’s modest productivity growth in the 2000s to rising demands for customization and increasingly frequent model renewals. As Holbein and Pil (2004) demonstrated, all major automakers have significantly expanded their range of models, variants, and equipment options since the 1960s – a trend that accelerated in the 1990s with the proliferation of minivans, SUVs, and crossover vehicles, along with shorter model life cycles. These developments posed considerable challenges for production. Coordinating workflows, particularly regarding logistics and labor deployment, became increasingly complex. Consequently, production disruptions became more frequent, operational efficiency declined, and productivity gains were constrained.

4.2 Consequences for the Workforce

The number of production workers in the automotive industry gradually decreased over time (Krzywdzinski, 2021), but, as with productivity, this was the result of a variety of factors. Further to automation and rationalization, relocation and outsourcing have played an important role in reducing employment in the studied companies. Conversely, increasing product differentiation has led to higher employment, particularly in assembly work. Combined with the low level of automation, the share of assembly work compared to other areas has steadily increased. However, overall, the level of employment has only decreased slowly in this way over the past decades.

In contrast to its quantitative effects, the footprint of automation is more directly observable through its impact on specific tasks and occupational roles. However, there is no straightforward causal relationship between technologically driven changes in production equipment and alterations in the task structures of individual jobs or occupational groups. The latter changes are shaped less by technology itself and more by processes of interpretation, negotiation, and adaptation, resulting in context-dependent patterns of labor division, institutional rules, and workplace practices. Consequently, significant national and company-specific variations can be observed.

The developments in the German case can be illustrated using the case of the Wolfsburg plant (Table 2; see Jürgens, 2023 for a more detailed analysis). Let us first consider the effects in the body shop. By the late 1970s, workers engaged in direct product-related tasks (e.g., welding) in the body shop had already become a minority compared to those involved in machine-related activities. The latter group included both simple machine operations (e.g., inserting parts) and more skilled tasks, such as quality inspection, setup, maintenance, and programming – all of which required higher qualifications. In 1978, workers performing these more advanced machine-related tasks still represented a minority. By 2015, however, they had become the clear majority.

In assembly, however, hardly anything has changed in the 40 years reviewed here. The proportion of workers with manual tasks stayed at around 70% at both points in time. The proportion of machine-related jobs had grown due to increased automation, but was still only around 11%.

Table 2: Change of Occupational Structure in the Body and Assembly Shops at the Wolfsburg plant (1978 and 2015)

|

Body Shop In % |

Assembly ShopIn % |

|||

|

1978* |

2015 |

1978 |

2015 |

|

|

I Product related manual jobs(welder, finisher, assembler, general worker) |

35.3 |

19.6 |

72.6 |

69.0 |

|

II Machine related jobs in total: |

39.1 |

66.7 |

2.8 |

11.3 |

|

a) machine-serving jobs (e.g., parts feeding) |

70 |

34 |

0.0 |

– |

|

b) upgraded production jobs (machinery monitoring, system regulation) |

19 |

36 |

1.6 |

4.1 |

|

c) skilled worker jobs (maintenance, etc.) |

20 |

30 |

1.2 |

7.2 |

|

III Other (quality, logistics, etc.) |

21.8 |

15.9 |

24.4 |

19.7 |

Note: The figures for 1978 refer to the complete body shop; the 2015 figures refer only to the production area for Golf. Source: Wobbe-Ohlenburg (1982, 240); own investigations.

The divergent development of employment structures in the body shop and final assembly is closely linked to their respective levels of automation. The rise in the proportion of workers engaged in higher-value tasks in production (Category IIb in Table 2) was also influenced by the works council, which emphasized that technological change should also yield benefits for semi-skilled workers. However, it should be noted that a substantial share of routine machine operation tasks, such as part insertion and logistics, has remained a consistent feature of production.

Automation also introduced machine-related tasks into assembly work at the Wolfsburg plant, although to a much more limited extent than in other production areas due to the measures described above. Except for a few automated zones, most assembly operations continue to rely on repetitive, line-based work. However, this continuity does not suggest that assembly tasks have remained unchanged. Rather, the nature of assembly work has evolved considerably, shaped by the introduction of teamwork, the integration of quality responsibilities, participation in continuous improvement initiatives, and ergonomic advancements. Nevertheless, more fundamental alternatives – such as those pioneered by Swedish car manufacturers in the 1970s and 1980s, which featured extended work cycles and stationary workstations (most notably at Volvo’s Uddevalla plant) – failed to achieve broader diffusion (Berggren, 1995).

5 Automation and the Shift to Electric Vehicle Manufacturing

Since the 2010s, the automotive industry has been undergoing a profound transformation. If the transition were limited to replacing the internal combustion engine with an electric drivetrain, the changes would appear relatively manageable, and vehicles could, in principle, continue to be manufactured largely on existing assembly lines. However, the changes are far deeper. Tesla is pursuing a new alternative approach. As the first company to achieve mass-production volumes with battery electric vehicles, it has introduced a business model that many competitors are now seeking to emulate (Boes & Ziegler, 2021). As an outlook, the following section offers a brief glance at this model – not as an established trend, but as a potential scenario for the future of automotive production. From a manufacturing perspective, Tesla’s approach, if widely adopted, could mark the beginning of an unprecedented wave of automation.

The software used in vehicles plays a central role in Tesla’s business model. The underlying assumption is that potential buyers no longer primarily base their purchasing decisions on hardware features, but rather on the functionalities offered by the software. Since the engine-transmission combination – previously a key dimension of product differentiation – does not exist in BEVs, the development of alternative forms of differentiation has become essential to appeal to diverse customer segments. Tesla’s strategy, described as “Software First,” prioritizes software-based functionalities while simultaneously minimizing the number of hardware variants and options. 2 This offsets the higher production costs resulting from the purchase of battery cells, which car manufacturers are currently still unable to produce themselves. This reduction of product variety opens up new possibilities. As demonstrated in the preceding chapters, the relentless proliferation of models, variants, and equipment configurations led to significant efficiency losses in the production systems of traditional automobile manufacturers – while simultaneously securing employment by driving up labor demand. A shift away from this complexity would, therefore, have far-reaching implications. It would not only serve as a major lever for reducing production costs but, through its standardizing effects, also facilitate higher levels of automation.

New possibilities for cost reductions and automation have also been advanced by Tesla through the economies of scale realized in the so-called Gigafactories. With an annual production capacity of up to one million vehicles, these facilities are significantly larger than the plants typically operated by traditional manufacturers today. They evoke a clear sense of déjà vu, recalling Ford’s River Rouge plant. As with the Rouge complex, the discourse surrounding the Gigafactories centers on labor-saving machinery.

In fact, automation through breakthrough technologies has become a defining feature of how Tesla presents its production system to the public. The prime example is the introduction of the so-called Giga Presses, or more precisely, gigacasting, which refers to a high-pressure aluminum casting process. Tesla uses this method to produce large sections of the vehicle underbody. Casting these segments in a single operation eliminates numerous tasks that previously required welding hundreds of individual components. In principle, this could result in significant labor savings; however, in most automotive companies, these welding operations have not been performed by human workers for decades. At Tesla as well, these tasks have already been conducted by industrial robots. The advantages of the casting method lie primarily in technical aspects – particularly the use of aluminum as a lightweight material for the car body – rather than in its potential for labor-saving automation.

More recently, gigacasting has become the starting point for another fundamental innovation. It is a concept for redesigning the production flow in assembly plants, which Tesla patented in 2023 under the name “Unboxed Manufacturing Process” (Weber, 2024; for a more detailed account, see Bleakley, 2023). If broadly adopted, this concept would significantly reduce the centrality of the traditional assembly line as the organizational backbone of vehicle production. While the approach holds potential for improving assembly working conditions, it could equally serve as a platform for further automation. A comprehensive assessment of the advantages and limitations of gigacasting, the Unboxed Manufacturing Process, and other disruptive technologies reportedly under consideration at Tesla (see, for example, Wang, 2023) lies beyond the scope of this article. Nevertheless, the potential for labor savings appears considerable. Gigacasting alone is reported to reduce production time per vehicle to approximately 10 labor hours (Lambert, 2021), and projections based on anticipated technological developments suggest this figure could decline to as little as 1 labor hour per vehicle (Wang, 2023).

However, whether such gains can be achieved in practice remains an open question. To date, few of these innovations have been implemented on a broad scale, and data on their costs and benefits are lacking. In addition, structural rigidities continue to present significant obstacles to the wider adoption of new production approaches. Thus far, none of these technologies has convincingly demonstrated a clear advantage over established manufacturing practices. Past experiences with highly ambitious automation projects in the automotive industry also justify a degree of skepticism toward the transformative promises currently being made.

All things considered, there is good reason to believe that the transition to EVs will be accompanied by a significant leap in production automation. However, this leap is unlikely to be driven primarily by disruptive technologies themselves. Rather, it is more likely to result from the broader business model shift toward a “Software First” paradigm.

6 Conclusions

The historical analysis of automation in the automotive industry offers several key insights that shed new light on current debates around automation.

First, the scope for further increases in the degree of automation is limited in most areas of production. While mechanical processing was already machine-dominated at Ford’s Highland Park plant, automation advanced considerably in the press, body, and paint shops over the following decades. In contrast, vehicle assembly has remained largely manual, with most attempts to automate this stage having been abandoned after a few years. By the early 1990s, automation had reached a preliminary plateau across the production areas examined in this study, with relatively little change observed since.

Second, the evolution of automotive automation has been shaped less by technological breakthroughs than commonly implied in narratives surrounding the so-called four industrial revolutions (Schwab, 2016). Ford’s leap forward in the early 20th century, for example, was not based on radically new technologies, but rather on the application of mechanical single-purpose machinery – technologies that had been developed long before. This type of equipment continued to serve as the foundation for automation efforts well into the 1980s and 1990s, even as more flexible automation technologies had already become available. The long-term trajectory of automation has thus been characterized more by processes of layering and hybridization than by periodic disruptions or technological ruptures.

Third, automation is not a guaranteed path to higher productivity. Time and again, automation has failed to deliver the anticipated increases in productivity – and thus in cost savings. As the analysis has shown, productivity gains have stemmed from a combination of factors. At Ford, for example, increased productivity resulted from both machine use and intensified labor through assembly lines and the five-dollar wage. A major obstacle to automation has been the rising complexity of production driven by greater product differentiation. Lean Production provided the most effective response to this challenge, but recent stagnation in productivity may be explained by increasing demands for customization and rapid model cycles. Tesla’s efforts to reduce hardware complexity indicate a return to this critical issue. Whether software-based differentiation can replace hardware options as a new paradigm remains to be seen.

Fourth, automation’s impact on employment is multifaceted and difficult to quantify. This complexity stems from the interplay of several factors: While automation, rationalization, and outsourcing generally exert downward pressure on employment, the increasing variety of products can simultaneously generate new jobs. Forecasts predicting large-scale job losses in the automotive industry – most recently in response to new process technologies associated with Industry 4.0 (Frey & Osborne, 2013) – have consistently proven to be exaggerated or inaccurate. Nevertheless, automation has significantly reshaped the occupational structure. In highly automated areas (e.g., press, body, and paint shops) traditional roles, such as welders and painters, have largely disappeared. They have been replaced by a polarized structure of machine-related jobs: On one side, simple tasks, like loading parts into machines; on the other, more demanding tasks, such as machine programming, supervision, and maintenance, which require higher qualifications. Over time, the proportion of these higher-skilled tasks has increased, although a significant number of low-skilled, machine-related jobs persist in modern factory settings. The assembly shop, however, remains a bastion of manual labor. The widely held assumption that routine tasks would be the first to succumb to automation has repeatedly proven inaccurate. Whether Tesla’s new product architecture will fundamentally alter this situation has yet to be determined.

Fifth, the shift to electromobility is likely to introduce a period of high uncertainty. New companies are entering the field, and legacy manufacturers must rapidly adapt their systems. Such concepts as “Software First,” gigacasting, and Unboxed Manufacturing may prove disruptive, but their success is far from certain. Competing approaches may arise from traditional automakers, newcomers from other industries, or the rapidly growing field of Chinese EV start-ups. Ultimately, there is no technological silver bullet, and history urges caution in overestimating technology’s ability to solve complex industrial challenges.

References

Abernathy, W. J. (1978). The productivity dilemma. Roadblock to innovation in the automobile industry. The John Hopkins University Press.

Abernathy, W. J., & Corcoran, J. E. (1983). Relearning from old masters: Lessons of the American system of manufactures. Journal of Operations Management, 3(4), 155 – 167.

Arnold, H. L., & Faurote, F. L. (1915). Ford methods and the Ford shops. The Engineering Magazine Company.

Automobil Produktion Special Edition. (1991). Sonderausgabe: VW, Dezember 1991. Media Manufaktur GmbH.

Automobil Produktion Special Edition. (1997). Sonderausgabe: VW Golf, Oktober 1997. Media Manufaktur GmbH.

Automobil Produktion Special Edition. (2003). Sonderausgabe: Der neue Golf V, Dezember 2003. Media Manufaktur GmbH.

Barclay, H. W. (1936). Ford production methods. Harper & Brothers.

Bartl, M. (1988). Hall 54: Experience and consequences. In H.-J. Warnecke (Ed.), Advances in assembly. Strategies, methods and lessons learned (pp. 427 – 440). Springer.

Berggren, C. (1995). Are assembly lines just more efficient? Reflections on Volvo’s “humanistic” manufacturing. In S. Babson (Ed.), Lean work. Empowerment and exploitation in the global auto industry (pp. 277 – 291). Wayne State University Press.

Biggs, L. B. (1987). Industry’s master machine: Factory planning and design in the age of mass production, 1900 to 1930. Massachusetts Institute of Technology.

Bleakley, D. (2023, March 2). Tesla flags paradigm shift in vehicle manufacturing as it looks to halve cost of EVs. The Driven. https://thedriven.io/2023/03/02/tesla-flags-paradigm-shift-in-vehicle-manufacturing-as-it-looks-to-halve-cost-of-evs/

Boes, A., & Ziegler, A. (2021). Umbruch in der Automobilindustrie. Analyse der Strategien von Schlüsselunternehmen an der Schwelle zur Informationsökonomie (Research Report). Institut für Sozialwissenschaftliche Forschung. https://doi.org/10.36194/IDGUZDA_Forschungsbericht_Auto

Bright, J. R. (1958). Automation and management. Harvard University.

Fisher, M., Jain, A., & MacDuffie, P. (1995). Strategies for product variety: Lessons from the auto industry. In E. Bowman & B. Kogut (Eds.), Redesigning the firm (pp. 116 – 154). Oxford University Press.

Ford, H. (1922). My life and work. Insomnia Press.

Frey, C.B., & Osborne, M. (2013). The future of employment: How susceptible are jobs to computerization? [Working Paper]. Oxford Martin School, University of Oxford.

Gordon, R. J. (2016). The rise and fall of American growth. The U.S. standard of living since the Civil War. Princeton University Press.

Granel, M. (1985). Auswirkungen des Robotereinsatzes auf die Arbeitsorganisation. REFA-Nachrichten, 4, 15 – 21.

Harbour, J. E., & Higgins, J. V. (2009). Factory man. Society of Manufacturing Engineers.

Holweg, M., & Pil, F. K. (2004). The second century. Reconnecting customer and value chain through build-to-order. The MIT Press.

Hounshell, D. A. (1984). From the American system to mass production 1800 – 1932. The development of manufacturing technology in the United States. The John Hopkins University Press.

Hounshell, D. A. (2000). Automation, transfer machinery, and mass production in the US automobile industry in the post-World War II era. Enterprise & Society: The International Journal of Business History, 1(1), 100 – 138.

Ingrassia, P., & White; J. B. (1994). Comeback. The fall and rise of the American automobile industry. Simon and Schuster.

Jürgens, U. (1998). Implanting change: The role of “indigenous transplants” in transforming the German productive model. In R. Boyer, E. Charron, U. Jürgens & S. Tolliday (Eds.), Between imitation and innovation. The transfer and hybridization of productive models in the international automobile industry (pp. 319 – 341). Oxford University Press.

Jürgens, U. (2023). Automatisierung und Arbeit in der Automobilindustrie. Von Henry Ford zur Industrie 4.0. Nomos Verlag.

Jürgens, U., & Krzywdzinski, M. (2009). Changing East-West division of labour in the European automotive industry. European Urban and Regional Studies, 16(1), 27 – 42. https://doi.org/10.1177/0969776408098931

Jürgens, U., & Krzywdzinski, M. (2016). New worlds of work. Varieties of work in car factories in the BRIC countries. Oxford University Press. https://doi.org/10.1093/acprof:oso/9780198722670.001.0001

Jürgens, U., Dohse, K., & Malsch, T. (1993). Breaking away from Taylorism. Changing forms of work in the automobile industry. Cambridge University Press.

Kern, H., & Schumann, M. (1984). Das Ende der Arbeitsteilung? Rationalisierung in der industriellen Produktion. Verlag C.H. Beck.

Krzywdzinski, M. (2021). Automation, digitalization, and changes in occupational structures in the automobile industry in Germany, Japan, and the United States: A brief history from the early 1990s until 2018. Industrial and Corporate Change, 30(3), 499 – 535. https://doi.org/10.1093/icc/dtab019

Kuhlmann, M. (2004). Modellwechsel? Die Entwicklung betrieblicher Arbeits- und Sozialstrukturen in der deutschen Automobilindustrie. Edition Sigma.

Lambert, F. (2021, November 5). VW CEO explains why it needs to be more like Tesla: Giga Berlin will produce 90 cars/hour on 1 line. Electrek. https://electrek.co/2021/11/05/vw-ceo-explains-why-be-more-like-tesla-giga-berlin-manufacturing/

MacDuffie, J. P., & Pil, F. K. (1997). From fixed to flexible: Automation and work organization trends from the international assembly plant study. In K. Shimokawa, U. Jürgens & T. Fujimoto (Eds.), Transforming automobile assembly (pp. 238 – 254). Springer.

Meyer, S. (1981). The five dollar day: Labor management and social control in the Ford Motor Company, 1908 – 1921. State University of New York Press.

Minchin, T. (2024). A broad battle: Public opinion and the 1945 – 1946 General Motors strike. Social History, 49(3), 367 – 396.

Moll, H. H. (1961). Die Entwicklungstendenzen der Automatisierung und Schlussfolgerungen für die Ausbildung in der Automobilindustrie. In Zentralstelle zur Erforschung & Förderung der Berufserziehung (Ed.), Automatisierung und Berufsausbildung (pp. 51 – 68). Bertelsmann Verlag.

Moll, H. H., & Ulbricht, W. (1957). Heutiger technischer Stand und Entwicklungstendenzen in der Automatisierung der Fertigung, am Beispiel einer Automobilfabrik. Werkstatttechnik und Maschinenbau, 47(3), 117 – 123.

Mommsen, H., & Grieger, M. (1996). Das Volkswagenwerk und seine Arbeiter im Dritten Reich. ECON.

Monden, Y. (1993). Toyota production system. An integrated approach to just-in-time (2nd ed.). Industrial Engineering and Management Press.

Noble, D. (1986). Forces of production: A social history of industrial automation. Oxford University Press.

Nye, D.E. (2013). America’s assembly line. The MIT Press.

Nomura, M., & Jürgens, U. (1995). Binnenstrukturen des japanischen Produktivitätserfolges. Arbeitsbeziehungen und Leistungsregulierung in zwei japanischen Automobilunternehmen. Edition Sigma.

Pardi, T. (2021). Prospects and contradictions of the electrification of the European automotive industry: The role of European Union policy. International Journal of Automotive Technology and Management, 21(3), 162 – 179.

Pavlinek, P. (2025). Europe’s auto industry. Global production networks and spatial change. Cambridge University Press.

Piore, M. J., & Sabel, C. F. (1984). The second industrial divide: Possibilities for prosperity. Basic Books.

Pope, E., & Tao, M. (2023, November 1). Gigacasting: The hottest trend in car manufacturing. S&P Global Mobility. https://www.euroguss.de/en/euroguss-365/2023/expert-knowledge/gigacasting-the-hottest-trend-in-car-manufacturing

Raff, D.M.F. (1991). Making cars and making money in the interwar automobile industry: Economics of scale and scope and the manufacturing behind the marketing. Business History Review, 65, 721 – 753.

Raff, D. M. G., & Summers, L. H. (1987). Did Henry Ford pay efficiency wages? Journal of Labor Economics, 5(4), 57 – 86.

Rosenberg, N. (1963). The American system of manufactures. Edinburgh University Press.

Schmitt, B. (2019). Inside Toyota’s Takaoka #2 line. The Drive. https://www.thedrive.com/tech/26955/inside-toyotas-takaoka-2-line-the-most-flexible-line-in-the-world

Schonberger, R. (2006). Japanese production management: An evolution – With mixed success. Journal of Operations Management, 25, 403 – 419.

Schumann, M., Baethge-Kinsky, V., Kuhlmann, M., Kurz, C., & Neumann, U. (1994). Trendreport Rationalisierung. Automobilbau, Werkzeugmaschinenbau, Chemische Industrie. Edition Sigma.

Schwab, K. (2016). Die Vierte industrielle Revolution. Pantheon Verlag.

Shimizu, K. (1998). A New Toyotaism. In M. Freyssenet, A. Mair, K. Shimizu, K., & G. Volpato (Eds.), One best way? Trajectories and industrial models of the world’s automobile producers (pp. 63 – 90). Oxford University Press.

Shimokawa, K., & Fujimoto, T. (Eds.) (2009). The birth of Lean – Conversations with Taiichi Ohno, Eiji Toyoda, and other figures who shaped Toyota management. The Lean Enterprise Institute.

Shingo, S. (1989). A study of the Toyota production system. From an industrial engineering viewpoint. Productivity Press.

Sorge, A., & Streeck, W. (2018). Diversified quality production revisited: Its contribution to German socio-economic performance over time. Socio-Economic Review, 16(3), 587 – 612.

Sorge, A., & Streeck, W. (1987). Industrial relations and technical change. The case for an extended perspective. Wissenschaftszentrum Berlin (WZB).

Sward, K. (1948). The legend of Henry Ford. Rinehart.

Tedlow, R. (1988). The struggle for dominance in the automobile market: The early years of Ford and General Motors. Business and Economic History, 17, 49 – 62.

Toyota Motor Corporation. (2012). Toyota: A 75-year history. https://www.toyota-glo-bal.com/company/history_of_toyota/75years/text/taking_on_the_automotive_business/chapter1/section1/item1.html

Ulrich, E. (1968). Stufung und Messung der Mechanisierung und Automatisierung, Teil I und II. Mitteilungen aus der Arbeitsmarkt- und Berufsforschung, 2, 28-43; 3, 102 – 126.

van Deventer, J. H. (1922). Ford principles and practice at River Rouge: I: Links in a complete industrial chain. Industrial Management, 64(3), 131-137.

Volkswagen Besucherdienste (2012). Gästebuch. Volkswagen AG.

Wang, B. (2023, September 19). Tesla will build a car in less than an hour like giant Lego. Next Big Future. https://www.nextbigfuture.com/2023/09/tesla-will-build-a-car-in-less-than-an-hour-like-giant-lego.html

Weber, A. (2024, September 12). Tesla details “unboxed” assembly process in patent. Assembly Magazine. https://www.assemblymag.com/articles/98770-tesla-details-unboxed-assembly-process-in-patent

Wenk, R. (2021, March 8). VW Trinity – Studie läutet Strategie Accelerate ein. NewCarz-Autonews Volkswagen. Newcarz. https://www.newcarz.de/2021/03/08/vw-trinity-studie-laeutet-strategie-accelerate-ein/

Wilhelm, B. (1997). Platform and modular concepts at Volkswagen – Their effects on the assembly process. In K. Shimokawa, U. Jürgens & T. Fujimoto (Eds.), Transforming automobile assembly (pp. 146 – 156). Springer.

Wilson, J. M. (2015). Ford’s development and use of the assembly line, 1908-1927. In B. Bowden, & D. Lamond (Eds.), Management history: Its global past and present (pp. 71 – 92). Information Age Publishing.

Wilson, J. M., & McKinlay, A. (2010). Rethinking the assembly line: Organization performance and productivity in Ford Motor Company, c. 1908-27. Business History, 52(5), 760 – 778.

Wobbe-Ohlenburg, W. (1982). Der Einfluß neuer Produktionstechnologien auf die Struktur der Automobilarbeit. Eine Fallstudie zum Einsatz von Industrierobotern im Volkswagenwerk Wolfsburg. Georg-August-Universität Göttingen.

Date received: February 2025

Date accepted: April 2025

1 The vocational training system and the availability of a highly qualified shopfloor workforce are often cited as key strengths of the German production model in debates about national business systems, particularly within the Varieties of Capitalism framework. With its emphasis on the ability to produce high-quality goods and manage product variety effectively, Sorge and Streeck (1987, 2016) characterized the German model as a system of Diversified Quality Production (DQP).

2 The extent to which VW is also aligning its EV strategy with the “Software First” principle became clear during the company’s planning for the transition to EV production in 2021. At the time, VW’s CEO stated: Future vehicle generations would be produced with significantly fewer variants. Individual configuration will no longer be determined by hardware at the time of purchase. The car will essentially come equipped with everything on board, and customers will be able to add the desired functions at any time on demand via the vehicle’s digital ecosystem. As a result, production complexity will be significantly reduced ” (quoted in Wenk, 2021).

Metrics

Downloads

Published

Issue

Section

License

Copyright (c) 2025 Ulrich Jürgens (Author)

This work is licensed under a Creative Commons Attribution 4.0 International License.